Subcontracting precision mechanical processing

CNC chip removal operations with a modern machine park and super-skilled operators. The in-house machining workshop can guarantee precision and productivity, quality control with a metrology lab for three-dimensional checks.

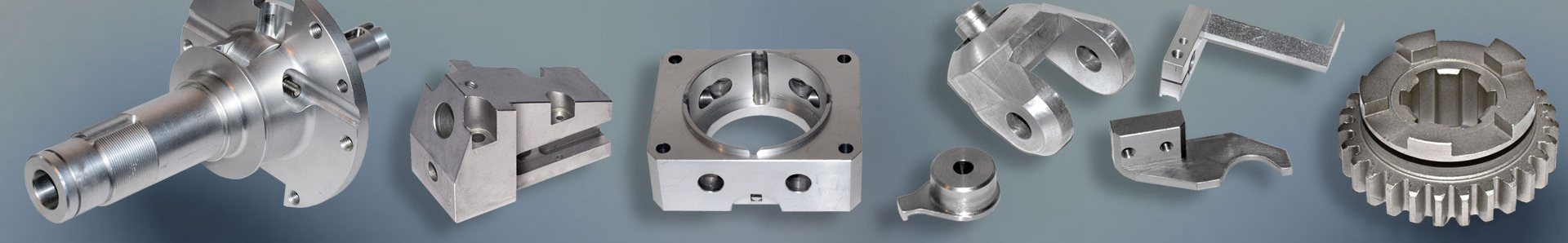

A partner to various companies operating in the main sectors of the mechanical engineering industry, Marpol FR dedicates a large part of its internal production organisation to subcontracting orders involving precision chip removal machining.

Our in-house workshop, which has been a major strength of our company for over forty years, in addition to machining parts for our machines, can carry out subcontracting orders for small, medium or large quantities. This is possible thanks to a fleet of machine tools made up of the latest generation of machining centres and operators featuring great capacity and high production potential assisted by the latest generation of CAD-CAM for the programming of sophisticated machining steps.

We can produce any component on the basis of drawings with many, even complex, CNC turning and milling cycles with quality guarantees thanks to a metrology department equipped with measuring machines for three-dimensional controls, altimeters, bench gauges, micrometers, comparators and roughness testers.

Machined materials

We can machine and manufacture parts from all kinds of materials and for a wide range of applications:

• ground, drawn and special heat-treatment steels •

• stainless steel •

• aluminium •

• brass and bronze •

• plastic materials •