Material processing technologies in the industrial processes.

Details, characteristics and differences.

“Wet” sanding to obtain even smoother and more finished surfaces means using water or cutting fluids during processing. For some manufacturing sectors it is essential.

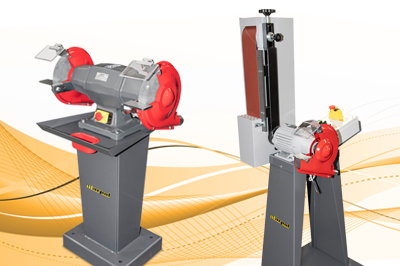

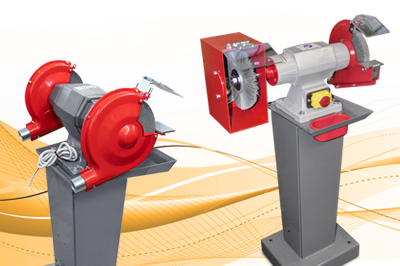

Insiders, professionals, know very well the difference between a grinder and a sander. Let us clarify.

In companies working in the precision engineering sector, in subcontracting in general, there is a need to cut metal and non-metal materials flexibly and quickly.

Fast dry machining to prepare metal surfaces for welding or simply for 45° chamfering of simple sheet metal or carpentry parts.

Satin finishing metals, an ideal process for our combined sanding machines. Also ideal for metal cleaning.

What does cleaning metal mean? What operations are involved? And which sectors are affected?

Professional polishing machines with abrasive belts or combined with brushes, for fast but indispensable metalworking processes.

With the use of rotating wheels the material removal process can be precision, roughing, rectification, cleaning.